Release time:2023-11-01

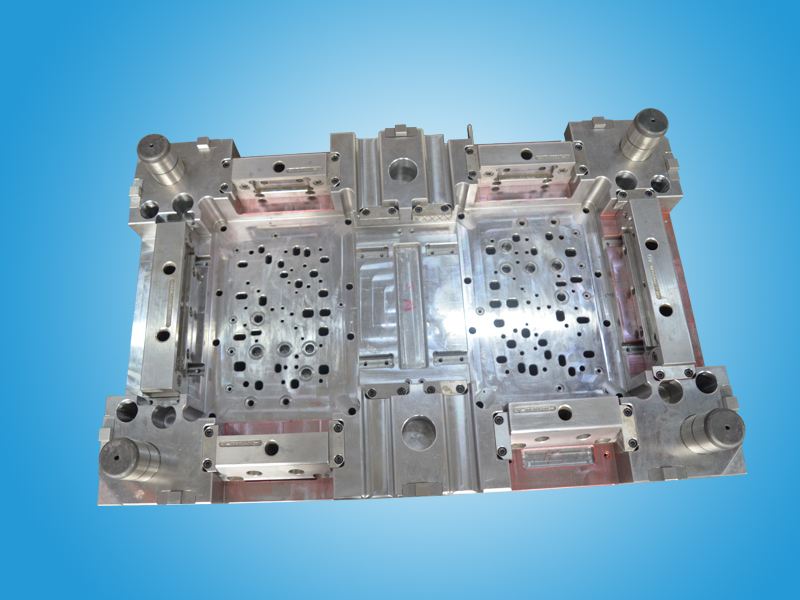

actually,Power supply plastic shellThe common processing mainly includes a female mold with variable cavity composed of a female mold combined base plate, a female mold assembly and a female mold assembly, and a chuck of a power supply plastic shell mold, and a male mold with variable core composed of a male mold combined base plate, a male mold assembly, a male mold combined chuck, a cavity cutting assembly and a side cutting combined plate. Coordinated change of punch, die and auxiliary molding system.

1. The mechanical strength is widely distributed and the strength is high: some of the processing products of the plastic shell of the power supply are hard products such as stone and steel, and some are soft products such as paper and leather; From the mechanical properties such as hardness, tensile strength, elongation and impact strength of the plastic, it has a wide range of distribution and a wide range of uses.

2. Excellent chemical stability: most plastics have good corrosion resistance to acid, alkali and other chemicals. Especially polytetrafluoroethylene (F4), its chemical stability is even better than gold, and it will not deteriorate after boiling in "aqua regia" for more than 10 hours.

3. Excellent electrical insulation performance: the products processed by the plastic shell of the power supply are all poor conductors, with large external resistance and volume resistance. The digital display can reach 109-1018 ohms. Therefore, plastics are widely used in electronic industry and machinery industry. At present, many plastic shell processing enterprises in Dongguan are gradually listed. The materials used include PC, PETG, PVC, pet, high resistance PS and other materials with good toughness.

The process flow of the plastic shell of the power supply is as follows:

1. Printing: almost all flat plastic shells can be printed. It can be processed as required. However, it is generally carried out in the dust-free workshop, and the printing effect of the plastic shell of the power supply will be better.

2. Bonding: the processing technology of the plastic shell of the power supply adopts imported special adhesive bonding PC, acrylic and other plastic shell materials to ensure the bonding strength, and the bonding position is not misplaced, with high accuracy, deformation, cracking and good appearance.

3. Polishing: the polishing of the plastic shell of the power supply is mainly used for the subsequent processing of the cutting or engraving parts of the plastic shell.