Release time:2024-08-01

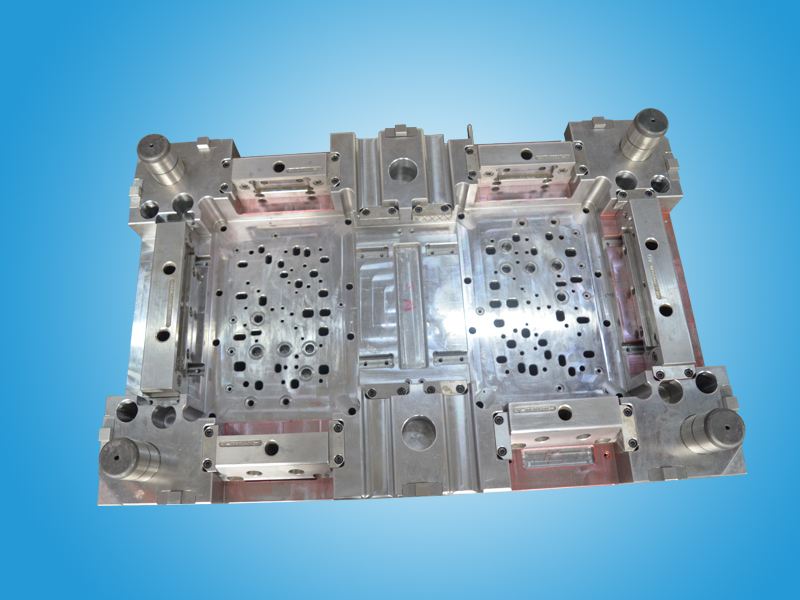

Mold processingIt refers to the processing of forming and blank making tools, as well as shear molds and die cutting molds. So what are the characteristics of mold processing?

1. High machining accuracy is required. A pair of molds is generally composed of a female mold, a male mold and a mold base, and some may also be multi piece assembled modules. Therefore, the combination of upper and lower molds, the combination of inserts and cavities, and the assembly between modules all require high machining accuracy. The dimensional accuracy of precision molds often reaches μ M level.

2. Complex shapes and surfaces. The surface of some products, such as automobile cover parts, aircraft parts, toys, household appliances, etc., is composed of a variety of curved surfaces, so the cavity surface of the mold is very complex. Some surfaces need to be processed by mathematical calculation.

3. Small batch. The production of molds is not mass production. In many cases, only one pair is often produced.

4. Multi process. Milling, boring, drilling, reaming and tapping are always used in mold processing.

5. Repeated production. The use of the mold has a long life. When the use of a pair of molds exceeds its service life, a new mold needs to be replaced, so the production of molds is often repetitive.

6. Profiling. Sometimes there is no pattern or data in the mold production, and it is necessary to carry out profiling processing according to the actual object. This requires high copying accuracy and no deformation.

7. The mold material is excellent and the hardness is high. Most of the main materials of the mold are high-quality alloy steel, especially the long-life mold. This kind of steel has strict requirements from blank forging, processing to heat treatment. Therefore, the preparation of processing technology can not be ignored, and heat treatment deformation is also a problem that needs to be seriously treated in processing. According to the above characteristics, the selection of machine tools should meet the processing requirements as much as possible. For example, the function of the CNC system should be strong, the accuracy of the machine tool should be high, the rigidity should be good, the thermal stability should be good, and the copying function should be provided.