Release time:2022-04-21

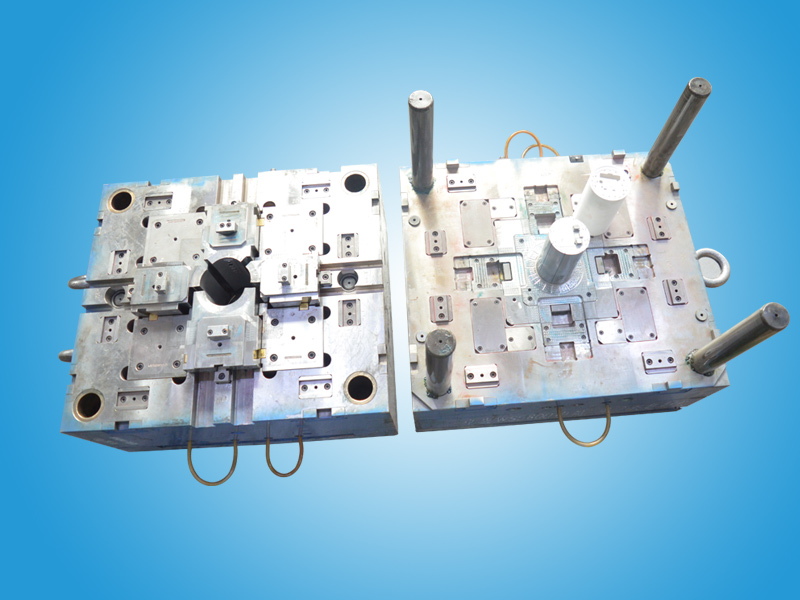

Injection molding is a common production method in industrial manufacturing. Is an important tool for mass production, so what are the basic requirements for injection mold processing?

(1) Ensure the quality of injection mold processing

The quality of injection mold processing refers to that under normal production conditions, the processed injection mold can meet the accuracy and appearance quality requirements specified in the drawings, and can produce qualified products in batches.

(2) Ensure the production cycle of injection mold processing

Injection mold manufacturing cycle refers to the completion of injection mold processing and production within the specified time. The length of injection mold manufacturing cycle also reflects the technological level and engineering strength of mold manufacturers. In mold processing, we should try to shorten the mold manufacturing cycle, which depends on the strength of the manufacturer.

(3) Ensure the service life of injection mold

The service life of the injection mold is short, and the accuracy of the working part remains poor, which will not only affect the product quality, but also waste the cost of manufacturing the mold. Therefore, extending the service life of injection mold has a significant impact on reducing the cost of plastic products and improving the productivity and competitiveness of enterprises.

(4) Ensure the low cost of injection mold processing

As an important tool of injection molding, the quality of mold directly affects the quality of products. Mold accounts for a large proportion in the development and production costs of enterprises. In order to reduce the production cost of injection mold, we should reasonably select mold materials and formulate reasonable processing flow according to the expected output of plastic products.