Release time:2022-03-30

The production process of plastic shell has always been a stage that requires your attention. If you can better understand the production process of plastic shell, the molding of plastic shell can be more smooth than the molding of all plastic shells. Therefore, in order to make it easier for us to understand the production and manufacturing of plastic shell, I provide you with a perfect production process of plastic shell, and look forward to providing you with some help.

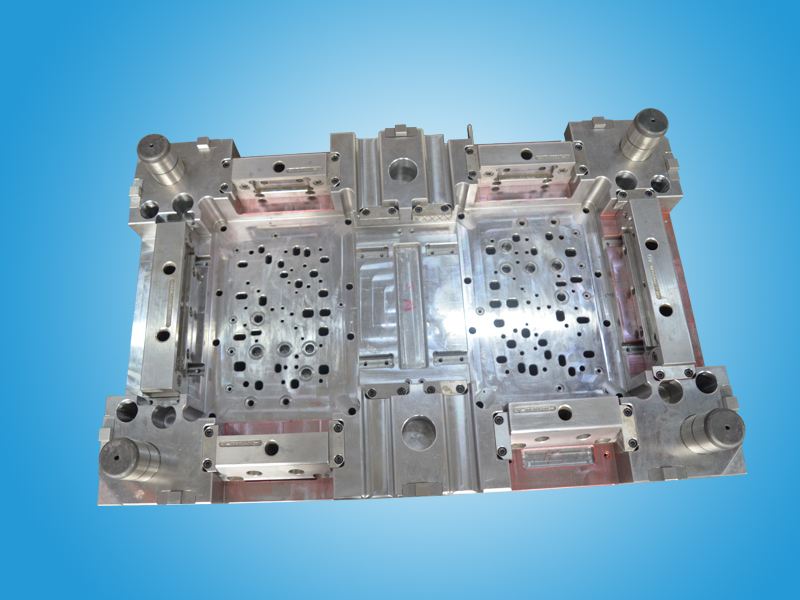

Production process of plastic shell I: the first step in the production process of plastic shell is to make corresponding preparations, prepare corresponding materials and moulds, and then prepare corresponding plastic shell moulds and raw materials of plastic shell, so that it is more convenient for everyone to produce plastic shell.

Production process 2 of plastic shell: after the preparation of raw materials and die-casting mold has been completed in advance, the manufacturing of plastic shell is in the process of mixed drying. The mixed drying stage is mainly to better prevent vacuum pump bubbles from appearing on the surface of plastic shell, make the moisture in raw materials volatilize fully, and make the plastic shell injection molding more solid.

Production process 3 of plastic shell: after the raw materials of plastic shell are solved, we need to carry out the injection molding process of plastic shell. In this process, we must adjust the production and processing temperature of plastic shell. Temperature control must be very critical, which determines whether the plastic shell can be carried out smoothly. Injection rate and inoculation method must also be paid attention to, because plastic shell injection molding may deform without paying attention to these two consciousness.

Plastic shell production process 4: after the above processes are completed, the fourth process is quality inspection, packaging, warehousing, so as to complete the process of all plastic shells.